As a factory with over ten years of experience in Tyvek bag manufacturing, Bene Bags has continuously refined its craftsmanship to ensure consistently high quality. It has become a trusted manufacturer of high-quality Tyvek bags for many businesses. We master specialized techniques for Tyvek material processing, precise cutting, advanced sewing technologies, and refined craftsmanship, ensuring every bag meets the highest production standards. Our specialized production model enables us to solve complex manufacturing challenges while maintaining efficient production capacity.

We source genuine DuPont Tyvek materials only through authorized channels, ensuring each bag thoroughly leverages Tyvek’s inherent lightweight, waterproof, and tear-resistant properties. This commitment to material authenticity forms the cornerstone of our manufacturing philosophy—we consistently use the highest quality materials because we deeply understand their importance to product lifespan, appearance, and functional reliability.

Whether you’re looking for a large-order supplier or a custom project partner, we can provide high-quality products that meet your requirements.

We understand the importance of efficiency and reliability to our customers, so we’ve optimized our production processes to ensure quick delivery while strictly maintaining quality.

Our door-to-door logistics service eliminates transportation concerns, allowing you to easily receive orders regardless of your location. We’ve established a global supply chain network, providing efficient and economical transportation solutions to ensure smooth, on-time delivery, helping you meet market demands.

Our services extend beyond manufacturing, covering the entire process from initial consultation, material selection, and production management to final delivery, ensuring your project proceeds smoothly and allowing you to focus on business development without worrying about production details.

As your Tyvek bag manufacturer, we are committed to building long-term cooperative relationships, consistently exceeding your expectations through quality products and efficient service!

Tyvek is a high-performance material renowned for its exceptional durability, ultra-lightweight properties, and unique texture. Bene Bags offers custom bags made from premium Tyvek with weights ranging from 35gsm to 105gsm, suitable for various application scenarios.

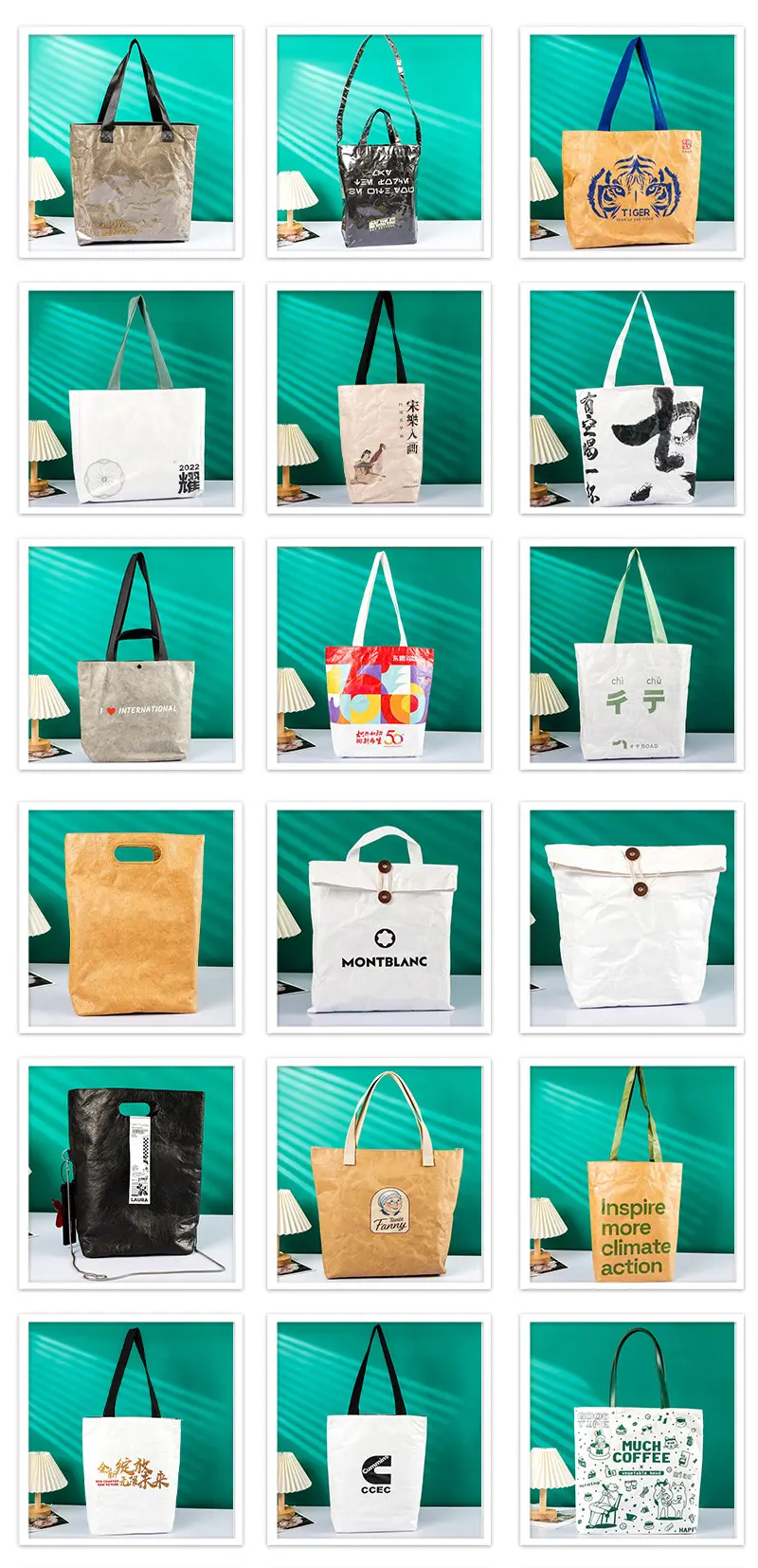

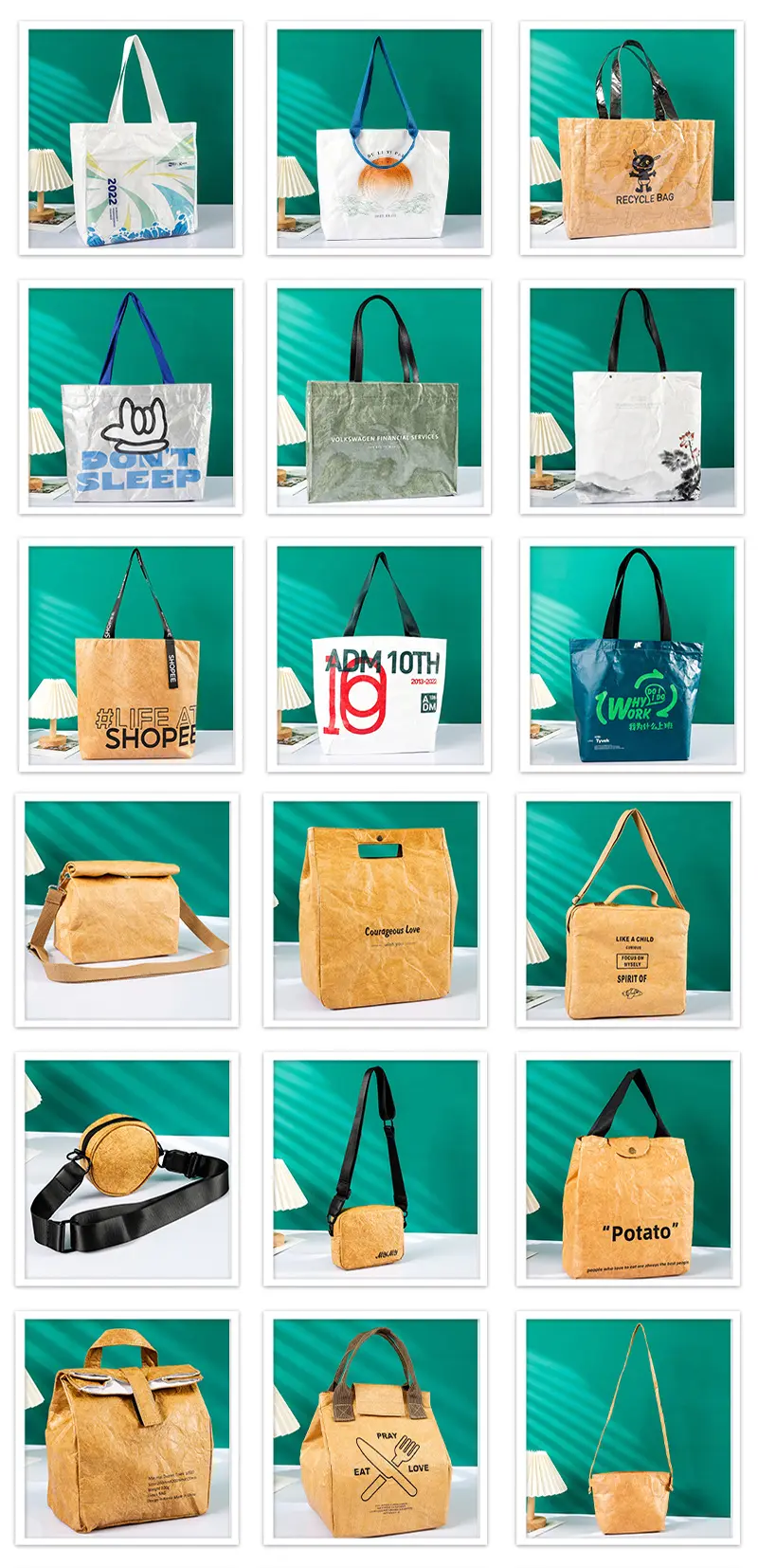

Beyond classic white Tyvek, we provide colored Tyvek series, textured surface treatments, PU coating, and composite options through innovative manufacturing processes. These treatments not only enhance visual and tactile experiences but also differentiate your products from similar items in the traditional market. Each custom Tyvek bag perfectly fuses material technology and practical design concepts.

Our custom Tyvek bag series encompasses a wide range of design styles, including elegant tote bags, practical shopping bags, modern backpacks, spacious duffle bags, and convenient drawstring bags. Additionally, we offer laptop sleeves, wrinkle-resistant garment bags, fashionable purses, practical storage bags, waterproof dry/wet bags, insulated lunch bags, and multipurpose pouches, fully utilizing the outstanding properties of Tyvek material.

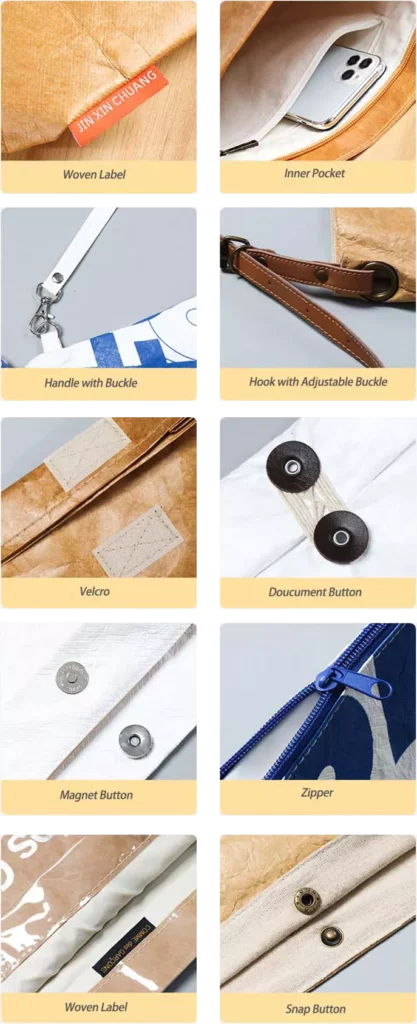

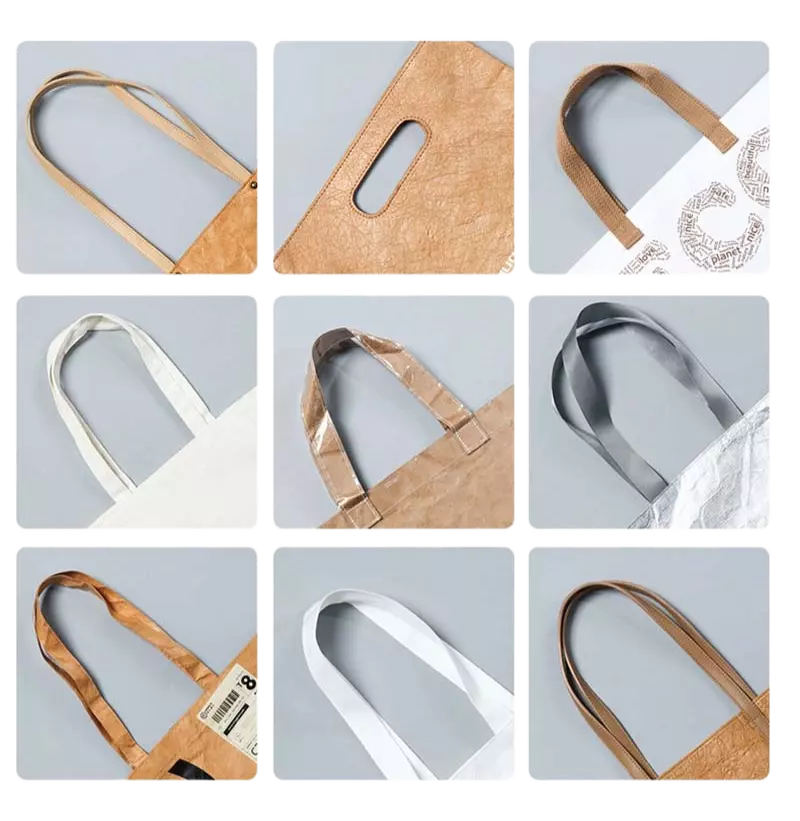

Every custom Tyvek project enjoys comprehensive personalization options. You can select Tyvek weight, color, and surface treatment, and enhance brand visual impact through screen printing, digital printing, or embossing techniques for logos and patterns. Furthermore, we can adjust handle designs, internal compartments, specialized pockets, smooth zippers, and secure closure systems according to your needs, ensuring perfect integration of functionality and aesthetics at all production scales—whether for small-batch retail orders or large-scale promotional customizations, we can precisely meet your requirements.

We can provide physical samples of custom Tyvek bags within days, allowing you to personally experience material quality, craftsmanship details, and design effects before formal mass production.

Our customization services extend beyond the sampling stage. Adhering to the concept of a long-term partnership, we offer professional advice on material selection, structural reinforcement solutions, and printing process optimization to ensure the finished product combines aesthetic impact with exceptional functional performance. This consultative collaboration model ensures your custom Tyvek bags meet current needs and add lasting value through careful design and precise execution.

Choosing Bene Bags means gaining a manufacturing partner dedicated to customer success, helping you create truly unique and high-quality Tyvek bag products.

| Item | Description |

| Material | DuPont Tyvek (High-Density Polyethylene Fabric) |

| Color | Available in stock colors or customizable to specific Pantone colors (achieved through printing or specialized dyeing processes). |

| Fabric Thickness | 35-105 gsm |

| Size | Customizable |

| Printing | Digital Printing, Screen Printing, Heat Transfer Printing, Flexography |

| Handle Type | Tyvek, Leather, Cotton, Nylon |

| Accessories | Inner Pocket, Outer Pocket, Zipper, Snap Button, Magnetic Snap, Velcro, Drawstring, Bottom Gusset, Side Gusset, D-ring, Buckles, Eyelet, Dividers, Tag, Label |

| Features | Lightweight yet durable, Water-resistant, Tear-resistant, Breathable, Eco-friendly and recyclable, Unique texture and appearance, Easily customizable |

| Usage | Promotional events, Shopping, Travel, Conferences, Exhibitions, Beach outings, Picnics, Daily use |

| Quality | Commitment to using premium materials and ensuring superior craftsmanship. |

| OEM/ODM | Acceptable |

| Sample Production | Lead Time: 3-7 days. Cost: Varies based on product details. Refund Policy: Custom sample cost fully refundable with an order of 1000pcs or more. Sample Delivery Options: UPS/FedEx/DHL/TNT/EMS. Note: Stock samples are provided free of charge; shipping fees are covered by the client. |

| MOQ | Our standard MOQ for Tyvek bags is 200 pieces. We can accommodate requests for smaller quantities, with preferential pricing offered for larger volumes. |

| Packing | PE Bag + Carton (Customizable) |

| Mass Production | 7-30 days depends on quantity |

| Shipment | By Express (DHL, UPS, FedEx, TNT, EMS), By Air, By Sea |

| Payment Term | 40% deposit upfront, a balance of 60% to be settled via T/T before shipment. For larger orders, a Letter of Credit is acceptable. |

| Place of Origin | China |

Tyvek is a unique nonwoven material developed by DuPont made from 100% high-density polyethylene (HDPE) fibers. It combines the best properties of paper, film, and fabric.

It is ideal for bag manufacturing because it is:

Tyvek bags offer a unique combination of performance and aesthetic appeal that sets them apart from traditional materials:

Due to their durability and unique aesthetic, custom Tyvek bags are widely adopted across diverse sectors:

Yes, Tyvek is a highly sustainable material choice.

We offer fully bespoke manufacturing solutions to match your brand identity. Since we are a direct factory, virtually every aspect of the bag can be customized:

Bene Bags’s typical minimum order quantity (MOQ) for custom Tyvek bags is 200 pieces. For larger quantities, we offer more competitive pricing. Our flexible approach allows us to cater to diverse customer requirements while maintaining high-quality standards and customization options for your Tyvek bags.

Our standard production lead time is 10 to 30 days after sample approval.

Yes, we can provide custom Tyvek bag samples for your review before bulk production. You can check the design, materials, and quality in advance. A sample fee and shipping cost will apply; however, the sample fee can be refunded or deducted once your bulk order reaches the agreed-upon quantity threshold.

Yes. Our production process is streamlined to ensure durability and print quality:

At Bene Bags, we implement rigorous quality control measures throughout our Tyvek bag production process. This includes initial material inspection, in-process checks during cutting and printing, and final product testing. Our QC team conducts random sampling and thorough inspections, checking for size, color, print quality, and overall construction consistency. We use specialized equipment to test durability, water resistance, and tear strength. All bags undergo a final inspection before packaging. We adhere to ISO 9001 standards to ensure our custom Tyvek bags consistently meet high-quality benchmarks.